When you have a. While they do increase the cost of the PCB the reliability and process consistency will offset the additional PCB.

How to Use Blind and Buried Vias in Altium Designer Working with Vias in Altium Designer.

Blind and buried vias. In a buried via only the inner layers of the board are connected by the via. Blind vias may be used for SMT or BGA pads. There are several options to choose from and we explore most of them here.

While they do increase the cost of the PCB the reliability and process consistency will offset the additional PCB cost. But not all combinations are possible. What is Buried Via.

The drilled holes can be plated or metalized to make them conductive or left bare. A common error is to call a blind via a microvia. Blind and Buried Vias Not all combinations are possible.

For bling and buried vias the holes are metalized. Blind and buried vias provide electrical connections from the outer layers to the inner layers as well as in between the inner layers and are used when you have limited space on your PCB. Blind and Buried Vias add considerably to the cost of a PCB.

According to the IPC a microvia is a via whose diameter is 8 mils or less whether or not it goes all the way through the PCB. This technology allows more functionality in less board space packing density. Configuring Altium Designer for Blind and Buried Vias.

Working through fabrication assembly and manufacturing youll want to make. Buried vias are hidden beneath the layers and free up surface space without impacting the traces or surface components on the top or bottom layers. It is specified by UL Underwriters Laboratories that three thermal press cycles are the maximum.

What is Stacked Via and. Blind via and buried via are not mutually exclusive and a design can employ either or both. Blind andor buried vias present in your data also need to be specified in your order details.

Blind and buried vias are used to connect between layers of a printed circuit board where space is at a premium. Because blind vias touch the surface on one. A buried via is a via between at least two inner layers which is not visible from the outer layers.

The increase in cost is because the layers have to be drilled separately assembled and then the holes are plated. Drilling is a fabrication process that involves making holes through the conductive layers and cores of a PCB. Todays high-density PCB frequently require at least the use of blind via to increase the yield at the fabricator and the assembler.

Unlike regular vias on a two layer board which connect the two surface layers buried and blind vias connect the inner layers with either other adjacent inner layers or adjacent surface layers. This is an advanced topic that will incur MUCH higher costs for your PC. Due to the increasing complexity of design structures blind vias and buried vias are increasingly used in high-density circuit boards.

Here we explore the OrCAD PCB Editor function of adding Blind and Buried Vias. Blind and buried vias add a lot to the cost of a multi-layer board and are only used on high-density high-performance systems. Blind vias connect one of the outer layers to one of more of the inner layers and a buried via connects two or more inner layers and cannot be seen on the outside of the PCB board.

Making of the blind and buried vias heavily depends on the drilling process. Now that were all up to speed on working with regular thru-hole. Blind vias and buried vias are not mutually exclusive and a design can employ either or both.

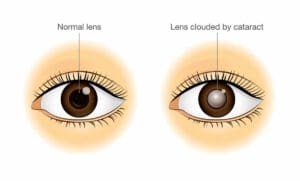

In a blind via the via connects the external layer to one or more inner layers of the PCB and is. When you have a very high density board you might need to use blind and buried vias. A blind via extends to only one surface of the printed circuit board.

This is done by selecting the appropriate build up in the Buildup Editor and the correct number of extra PTH runs and extra press cycles that are applicable. A blind Via connects exactly one outer layer with one or more inner layers. Todays high-density PCBs frequently require at least the use of blind vias to increase the yield at the fabricator and the assembler.

Connects an inner layer with the adjacent surface layer they are only visible on one side of the boards and so are called blind vias. Blind Buried Vias. They should only be used when absolutely necessary.

Blind Via and Buried Via What is Blind Via. When a via passes between two inner layers of a PCB but does not touch either surface it is a buried via.